FLEXDEB

FINISHING AND DEBURRING

STANDARD CELL - TECHNICAL INFORMATION

- Work Envelope: 1,4m³ / 50ft³

- Load capacity (part+fixture weight): 500kg / 1,100lbs

- Weight (equipment): 5000kg / 11,000lbs

- Number of axes: 9 (7 simultaneous harmonized)

- Station mobility: 360°

- Tool magazine: Up to 8 positions

- Electric spindle power: 15_25KW

- Tool Compatibility: Diamond - Organic - Carbide - High-Speed - Steel

- Robot: ABB, KUKA or FANUC - Foundry line

- HMI & PLC: Allen-Bradley and Siemens

ADVANTAGES

AUTOMATIC DIMENSIONAL COMPENSATION FOR THE PART

GREATER WORKING FLEXIBILITY WITH UP TO 7 DEGREES OF FREEDOM

MONOBLOCK STRUCTURE, HIGHLY ROBUST, PROVIDING LAYOUT FLEXIBILITY

AUTOMATIC ADJUSTMENT IN RELATION TO THE ABRASIVE DIMENSIONAL VARIATION

AUTOMATIC DRESSING OF GRINDING WHEELS (NON-DIAMOND)

CAD/CAM FOR ROBOTS VERY EASY TO PROGRAM

HIGH-PRECISION AND HIGH-SPEED ROTATING TABLE

Request your quote now!

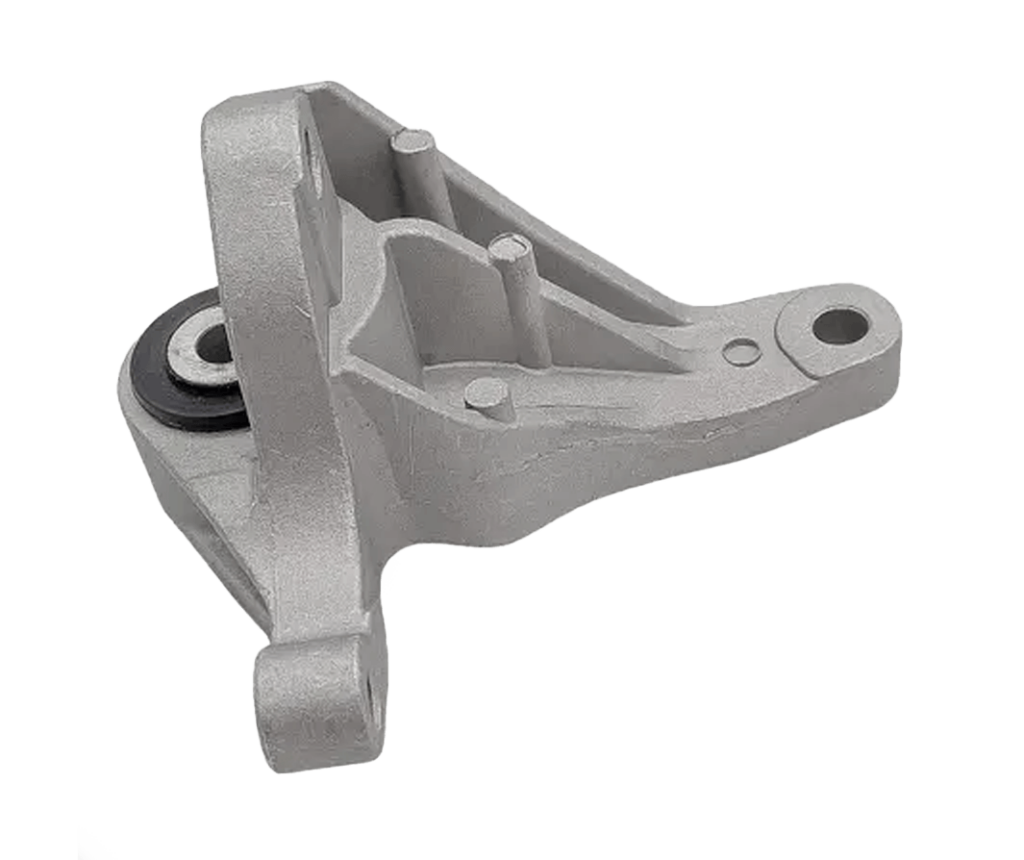

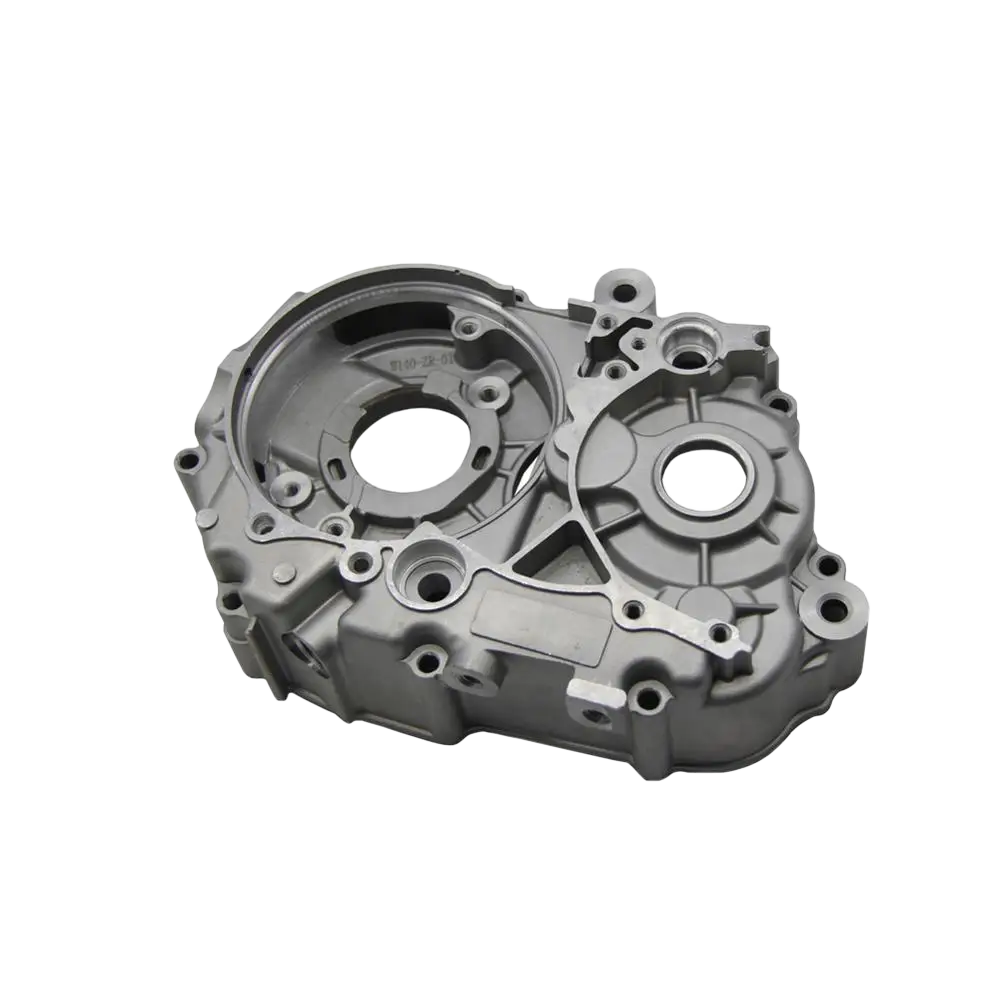

FINISH COMPLEX PARTS AT A DALCA CELL UNIT

CLIENTS

FROM TO

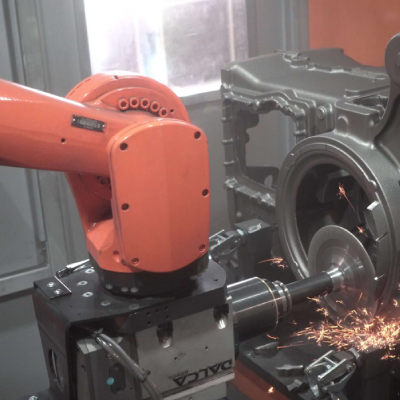

SPECIAL ROBOTIC DEBURRING CELL

Dalca’s robotic cells efficiently handle deburring, sanding, polishing, and cutting tasks within enclosed workstations. These cells include an exhaust system, acoustic booth, rotating table, and integrated equipment for various needs. Robots could pick up parts from the table, process them, and return them to the table for the next operation. Some models feature 3D and 2D vision systems for precise identification and verification. The cells are suitable for applications in cast iron, aluminum, plumbing fixtures, and steel.

For a special robotic deburring cell, talk to a Dalca specialist.

ABOUT DALCA

The expertise in developing robotic and Industry 4.0 solutions positions Dalca Brasil as one of the leading Brazilian companies in generating technology for the industrial sector!

The company began its operations in 2007, specializing in industrial robotics and internal logistics automation. Demonstrating its commitment to continuous process improvement and growth to better meet market demands, the company took a significant step with the ambitious project of expanding its business: the construction of a new headquarters in Bento Gonçalves – Brazil, which increased production capacity.